MI INFRASTRUCTURE

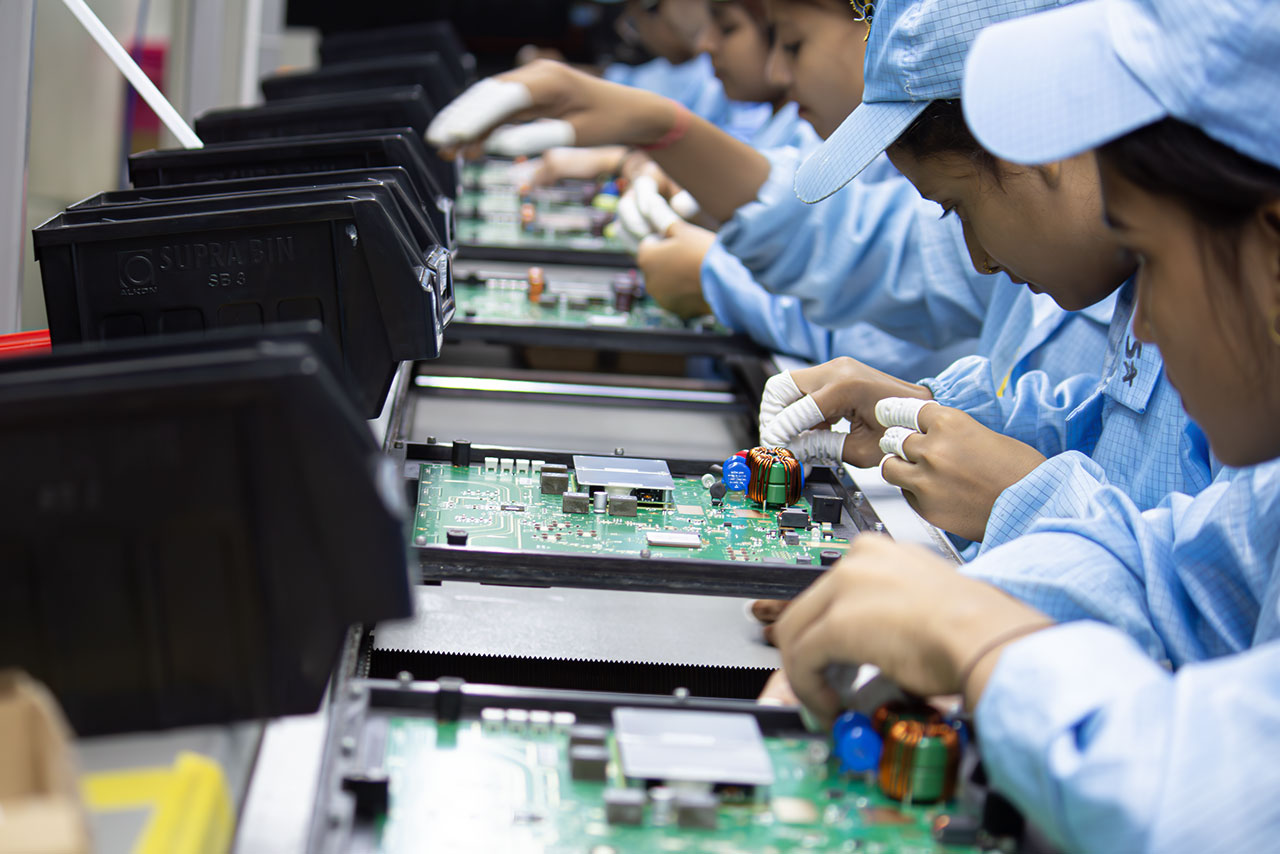

In the dynamic landscape of Electronics Manufacturing, where automated assembly has become synonymous with efficiency, there are instances where a human touch is irreplaceable. Optiemus Electronics Limited recognizes this, and this is where Manual Insertion (MI) plays a pivotal role, ensuring the assembly of PCBs with unmatched accuracy.

OEL boasts four manual insertion lines, each with a capacity of over 25,000 component insertions per hour. This impressive capability translates to more than 2 lakhs component insertions per day, showcasing the company’s commitment to efficiency and scale. At the heart of our MI infrastructure is a dedicated and skilled workforce. With a total manpower of 200 workers, the company has a diverse team of best engineers, skilled workers and component testers.

To complement the manual insertion process, OEL integrates four Wave Soldering Machines, each equipped with an ultrasonic fluxer unit. This advanced technology enhances the soldering process, guaranteeing a seamless connection between components.

Our infrastructure for Manual Insertion is a testament to the company’s dedication to precision and manufacturing. The integration of skilled manpower and cutting-edge technology solidifies OEL’s position as a leader in EMS.