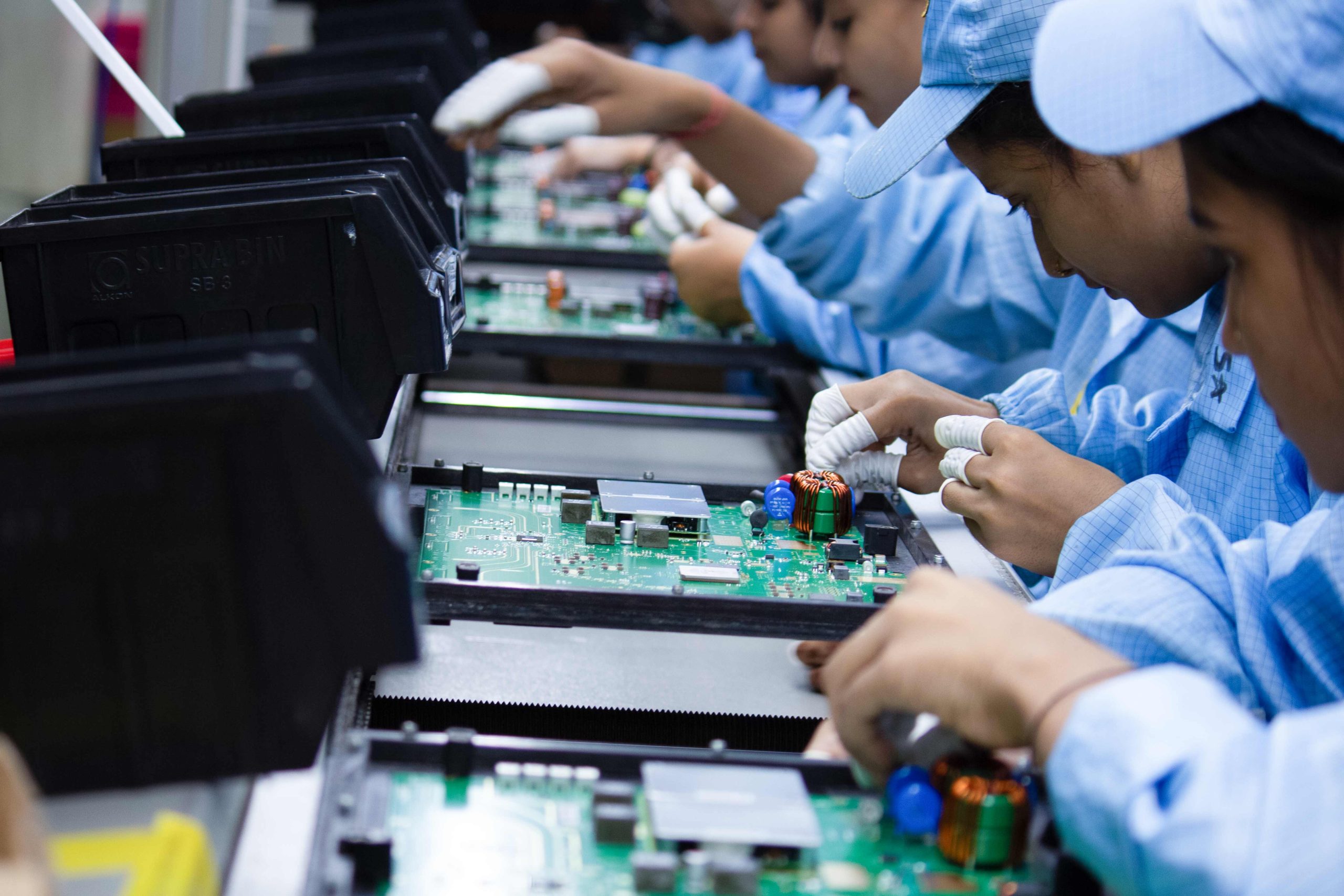

MANUAL INSERTION (MI)

PCBs are the backbone of today’s electronics. It would be impossible to construct any modern gadget without them. It is therefore vital to have a dependable, strong and proven method of PCB assembly and that’s where our manual insertion method comes into the picture.

While automated assembly offers the consistency and speed necessary for market competitiveness, certain situations call for manual assembly of components. There are instances where a human touch is essential in the assembly of a PCB, as not all components can be adequately inspected by automated optical systems.

At times due to the process SOP or uniqueness of the PCB design, precision Manual Insertion Services are required. OEL engineers and workforce are highly trained, skilled and experienced in this area.

Our team of engineers engage in the MI process, where electronic components are carefully placed into the circuit boards. Precision and excellence are ensured throughout.

Our technicians meticulously verify the component placement and address any soldering issues. In the PCBA manufacturing process, we have striked to achieved the perfect balance by combining both automated techniques and the finesse of manual insertion.

We manufacture with precision and no day passes without a quality check. Get in touch with us to know more about our electronics paced world.